-

Products

- Cookware

- Ovenware

- Knives

- Kitchen appliances

-

Kitchenware

- Measuring utensils

-

Utensils for decorating

- Appliances and knives for spiraling

- Plate decoration

- Fruit and ice cream cups

- Decorating knives

- Utensils for decorating drinks

- Cake Pops molds

- Biscuit molds and cutters

- Ice cream molds

- Molds for marzipan and chocolate

- Decorating platters

- Whipped cream siphons

- Decorating sets

- Food and drink decorating shakers

- Icing syringes, pastry nozzles and piping bags

- Serveware

- Drinkware

- For preparing drinks

- Pasta-making tools

- Storage and organization

- Outdoor activities

- Cleaning items

- Home items

- Cook Books

- Beauty products

- Wines

- Brands

- New products

- KitchenShop Loyalty Program

- Contact us

-

Back

-

Products

- Products Back

- New products

-

Cookware

- Ovenware

- Knives

-

Kitchen appliances

- Kitchen appliances Back

- Processing and mixing

- Cooking appliances

- Sandwich, toast and boiled eggs

- Popcorn poppers

- Juices and desserts

- Cordless electric appliances

- Household appliances accessories

- Tea and coffee

- Electric hobs

- Climate control equipment

- Food storage

- Electric knife sharpeners

- Smart planters

-

Kitchenware

- Kitchenware Back

- Cooking utensils

- Measuring utensils

-

Utensils for decorating

- Utensils for decorating Back

- Appliances and knives for spiraling

- Plate decoration

- Fruit and ice cream cups

- Decorating knives

- Utensils for decorating drinks

- Cake Pops molds

- Biscuit molds and cutters

- Ice cream molds

- Molds for marzipan and chocolate

- Decorating platters

- Whipped cream siphons

- Decorating sets

- Food and drink decorating shakers

- Icing syringes, pastry nozzles and piping bags

- Utensils for cutting, chopping and peeling

- Salad spinners

- Spice grinders

- Kitchen textiles

-

Serveware

-

Drinkware

-

For preparing drinks

- Pasta-making tools

-

Storage and organization

- Storage and organization Back

- Jars and bottles

- Food storage containers

- Bread boxes

- Storage and holders

- Sink racks and accessories

- Spice containers

- Universal storage containers

- Cutlery organizers and holders

- Spice racks

- Refrigerator storage and organization

- For resealing bags

- Labels for jars and food

- Outdoor activities

- Cleaning items

- Home items

- Cook Books

- Beauty products

- Wines

- Brands

AMT Gastroguss

AMT Gastroguss – "The world's best pan"

We do not say it ourselves, but VKD - the largest association of chefs in Germany.

From the design to the finished product, AMT Gastroguss cookware are designed to cover a wide range of needs in the kitchen, being of excellent quality, confirmed both by the annual awards obtained, by the conventional and unconventional quality tests (the combat vehicles could not flatten out the AMT saucepan), and by the strong popularity they enjoy among the best chefs in the world.

The strengths of AMT Gastroguss cookware are Quality, Efficiency and Strength, attributes generated by all the details that compose them, starting from the special way of manufacturing, the high quality material used, their structure and the intelligent arrangement of the built-in layers and due to the handles and related accessories.

AMT Gastroguss cookware also protect the environment by reducing energy consumption, being the first cookware of this type classified in energy class A, due to the efficiency with which aluminum transfers heat.

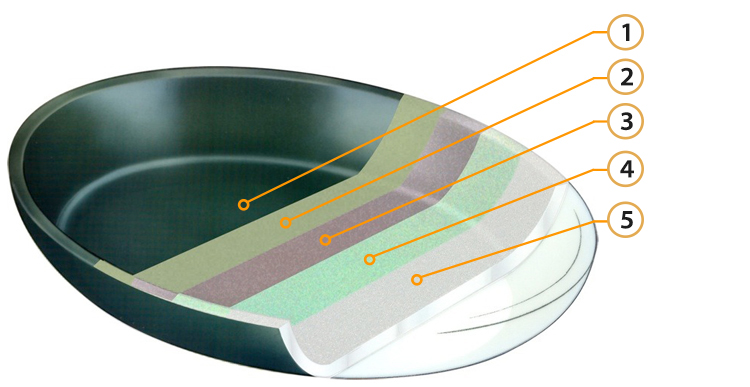

The structure of the AMT Gastroguss cookware is as follows:

- The first layer, cast by hand, of sandblasted aluminum. Sandblasting has a role in increasing by 12 times the adhesive surface of the layers to be applied on it, and the manual casting is homogeneous, compared to the automatic casting, which contributes to the longer curing time, which prevents material stress and occurring bags of air that would slow down the heating process.

- The hard layer of titanium oxide, burned at 20.000°C, is almost as hard as diamond.

- Anticorrosive layer with the role of stopping the corrosion that could occur over time.

- Layer containing ceramic particles.

- Non-stick Lotan® surface coating, specific only to AMT Gastroguss cookware and patented by this company. This non-stick coating gives all the advantages of a classic non-stick coating, allows easy cleaning, has antibacterial effect, but does not contain PFOA, the toxic substance used in manufacturing Teflon.

Structure of AMT Gastroguss cookware

1. Non-stick Lotan® coating

2. layer with ceramic particles

3. anti-corrosive layer

4. hard layer of titanium oxide

5. sandblasted aluminum

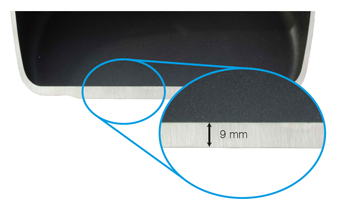

Gastroguss AMT cookware has a very thick base, up to 9 mm, which stores more energy, does not overheat easily and does not deform, even if it is subjected to extreme temperature variations. These qualities allow for cleaning the AMT products in the dishwasher, but the best method of cleaning them remains warm water and liquid dishwashing detergent.

The sturdy ergonomic handles of Gastroguss cookware have been developed with the help of the National Culinary Team of Germany, withstand high temperatures of up to 240°C and thus allow for gratinating food immediately after roasting on the hob and the cooking dish does not need to be changed.